At UV Knowledge Link Pvt. Ltd., we specialize in delivering high-precision engineering solutions tailored for the Aerospace & Defense sector. Our expertise encompasses a wide range of services, from design development to manufacturing, ensuring stringent adherence to industry standards and customer requirements.

Successfully Delivered Projects

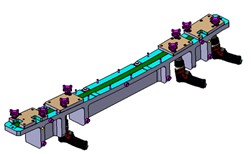

Drilling and milling jig Design and Manufacturing

Client: TAL Manufacturing Solutions, Nagpur

Description: Designed and manufactured custom jigs for drilling and milling applications, ensuring high accuracy and reliability for aerospace components.

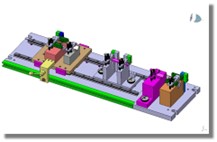

Design and Manufacturing of Fan Cowl (737) Drill Jigs and NCMF for Boeing - 20 Fixtures

Client:Tata Advanced Systems Limited (TASL), Nagpur

Description:Developed and produced 20 fixtures, including drill jigs and NCMF, specifically for the Boeing 737 fan cowl, meeting the stringent quality and precision standards required by the aerospace industry.

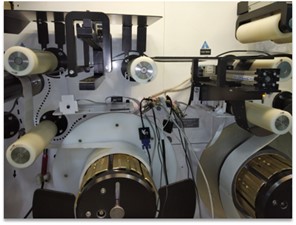

Client:Tata Advanced Systems Limited (TASL), Nagpur

Description:We successfully developed and implemented an Advanced Vision Inspection (AVI) system for TASL in Nagpur. Utilizing deep learning techniques, this system is capable of detecting and analyzing various defects such as scratches, part markings, left-hand (LH) and right-hand (RH) orientation of parts, and dents. The integration of this AVI system has significantly enhanced quality control processes, ensuring higher accuracy and efficiency in identifying imperfections and maintaining product standards

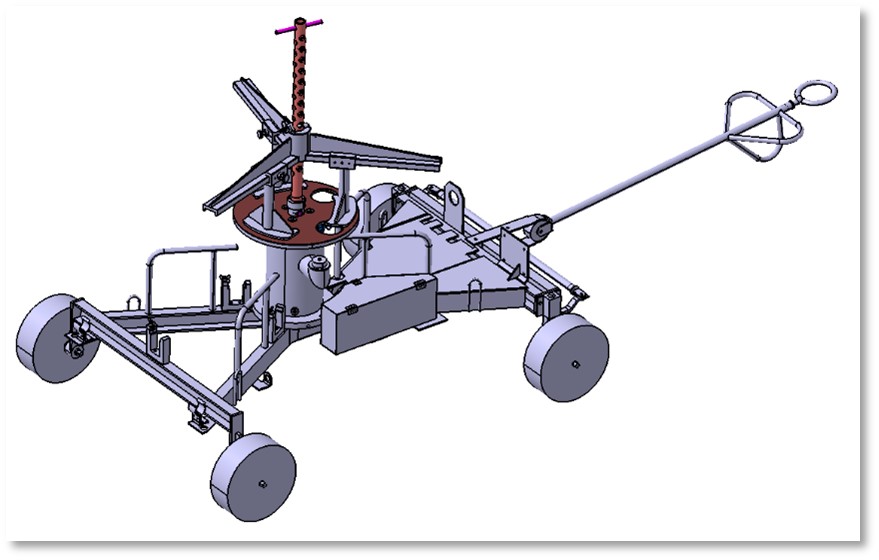

Client:HAL, Nashik

Description:We proudly developed and delivered a specialized Tyre Removing Device as Ground Support Equipment (GSE) for the Su-30MKI aircraft to Hindustan Aeronautics Limited (HAL) in Nashik. This project involved the design and fabrication of a robust and efficient device tailored to the specific requirements of the Su-30MKI aircraft. The equipment ensures safe and swift tyre removal, significantly enhancing maintenance operations and reducing downtime. Our solution supports HAL's commitment to maintaining the highest standards of operational readiness and aircraft safety.

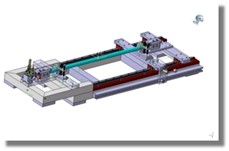

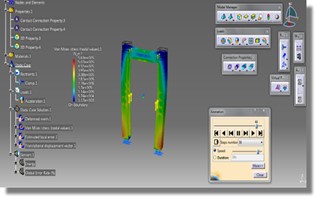

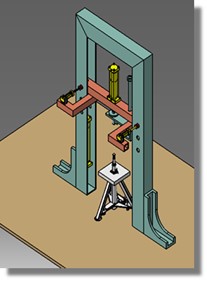

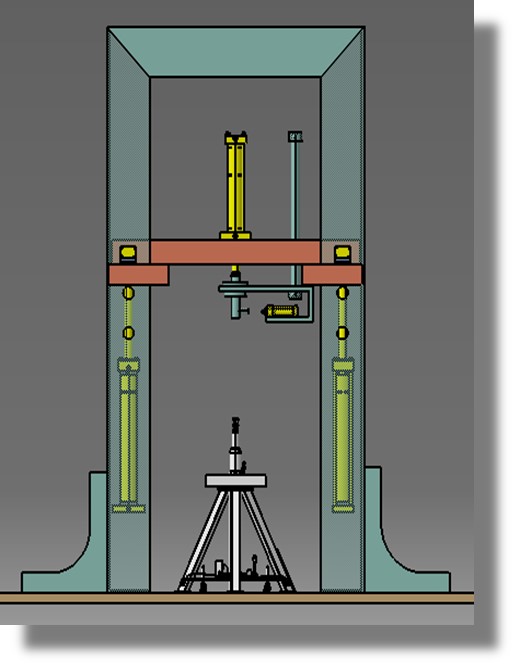

Client:HAL Hindustan Aeronautics Limited, Nasik

Description:We designed and developed a specialized Jack Testing Rig for Hindustan Aeronautics Limited (HAL) in Nasik. This project involved creating a robust and precise testing rig capable of assessing the performance and reliability of jacks used in aerospace applications. Our design ensures high accuracy and safety standards, facilitating HAL's quality assurance processes and contributing to their mission-critical operations in the aerospace industry.

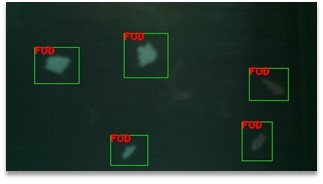

Client:Tata Advanced Systems Limited (TASL), Nagpur

Description:We successfully developed and deployed a sophisticated Foreign Object Detection system for TASL in Nagpur. This system leverages advanced technologies to accurately detect and analyze foreign objects based on their color, size, and quantity. The implementation of this system has greatly enhanced TASL's quality control measures, ensuring the integrity and safety of their products by preventing contamination and ensuring precise classification of detected objects.

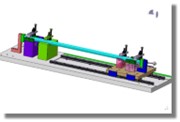

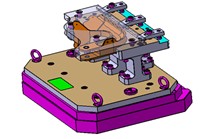

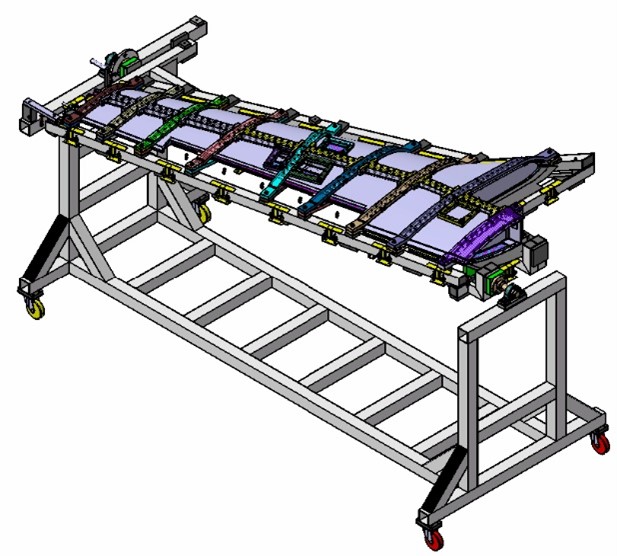

Client:ADE (Aeronautical Development Establishment) Bangalore, through Godrej Aviation, Mumbai

Description:We successfully designed and delivered a comprehensive trimming, drilling, and assembly fixture for the horizontal wing project of the Aeronautical Development Establishment (ADE) in Bangalore. This project, executed through our collaboration with Godrej Aviation, Mumbai, involved creating a highly precise and robust fixture system. The solution facilitated accurate trimming, drilling, and assembly processes, ensuring superior alignment and quality in the production of the horizontal wing components, thereby enhancing the overall efficiency and reliability of the manufacturing process.

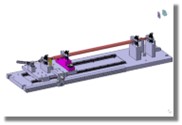

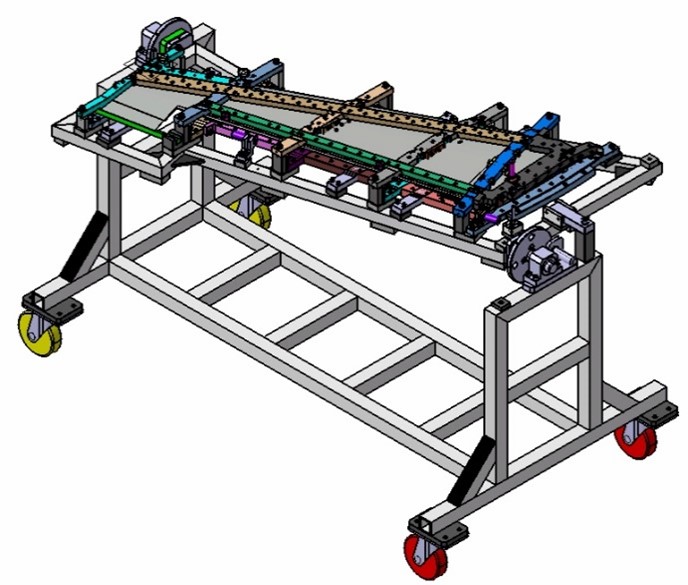

Client: ADE (Aeronautical Development Establishment) Bangalore, through Godrej Aviation, Mumbai

Description:We successfully delivered a precision-engineered trimming, drilling, and assembly fixture for the winglet of the Aeronautical Development Establishment (ADE) in Bangalore, through our collaboration with Godrej Aviation, Mumbai. This project involved the design and development of a sophisticated fixture system that ensures accurate and efficient trimming, drilling, and assembly processes. Our solution significantly enhances the production quality and assembly precision of the winglet components, contributing to the overall advancement of aeronautical engineering standards